WECO: Phygital Kanban

WECO Srl was established in 1997 and has since become one of the most solid industrial realities in the professional welding market, thanks to a range of highly technological products capable of meeting every need in TIG, MIG, and MMA welding processes.

The production, 100% made in Italy, is certainly one of the most robust processes within the company and has been further enhanced after the recent relocation to the new facility in Cittadella (PD), a modern two-story building covering 6,000 square meters.

The ownership and management have always supported:

- The implementation of the lean system as an essential means to make the company effective, efficient, and capable of meeting high growth trends

- The implementation of modern software to facilitate information flow management: Advanced Planning and Scheduling (APS) software, Manufacturing Execution System (MES) software, and Warehouse Management System (WMS) software

Among the various successful lean techniques and tools applied in previous lean transformation projects, the management pull kanban is also found at different levels:

- Production kanban to replenish the finished product supermarket

- Component transfer kanban from the raw material supermarket to the line-side supermarkets

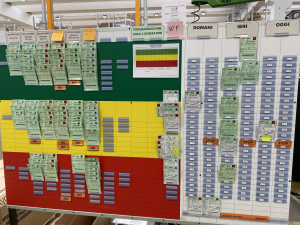

In addition, Heijunka is used for short-term visual scheduling, which allows for leveling production flows for both make-to-stock (MTS) finished products and make-to-order (MTO) custom items.

Example of Kanban Board and Heijunka Board at WECO Srl

In 2022, the WECO team, led by engineer Piantanida (Operations Manager), collaborated with the KanbanRocket engineering team on an innovative “PHYGITAL” kanban project. This project aimed to preserve and enhance all the benefits already obtained in the physical realm while incorporating digital aspects.

The main objective of the project was to achieve all the advantages of electronic kanban while maintaining all the physical tools and standards already implemented with their original paper format.

Results achieved:

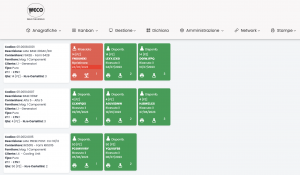

- Creation of digital replicas of physical boards to streamline internal communication between production and other involved functions within the company

- Introduction of a tool for proactive maintenance of kanban links as consumption changes.

- Automation of production order entry into the company’s ERP system and integration with planning tools, namely APS software (medium-term) and heijunka (short-term)

- Automation of updating the completion status of kanban production orders with signals from the MES software

- Integration with WMS software for automatic creation of component transfer missions from the raw material warehouse to the line-side supermarkets

- Automation of updating the completion status of transfer kanban orders with signals from the WMS software

Example of customized prints transitioning from paper kanban to electronic kanban (from left: original print of a kanban card at WECO, print parameterization in KanbanRocket, print of an electronic kanban from KanbanRocket)

Electronic tracking of cards also positioned in physical kanban boards

This is an excellent example of advanced application in a hybrid context (MTS-MTO) where the WECO and KanbanRocket teams have succeeded in integrating and streamlining processes by intelligently digitizing information, providing an updated, transparent, and easily interpretable visual information for the entire production team.

Truly an outstanding job!

comments