VaninAlluminio srl

“Vanin Orlando e figli snc” was founded in 1985 as a small carpentry manufacturer of furniture and doors and windows and then specialized mainly in the production of blinds and shutters for third parties.

Since the early years, the company has been able to rapidly expand its customer portfolio, reaching all the regions of Italy and thus managing to record strong growth in terms of volume and turnover.

Since 1990, major investments have been made in state-of-the-art production facilities: a virtuous path that led to the birth of Vanin srl, a name recognized by the most important magazines in the sector.

In 2008, with the arrival of the first signs of the real estate crisis, the Vanin brothers decided to restructure and innovate their business model in a courageous and prompt way.

This path of change, among other initiatives, has also led to the creation of a product concept entirely in aluminum that manages to combine the sinuous design and the charm of wood with the durability of metallic materials.

Thus, in 2011, the company invested in a new business unit dedicated to the production of aluminum blinds highly appreciated by the market for their aesthetics and quality.

This is the beginning of a new important growth path that in 2019 led the owners to start a lean & digital transformation project given the need to increase the capacity of the processes and design a new plant layout.

Since 2020, the continuous increase in demand has required further strengthening of the Aluminum business unit by integrating all the previously shared company functions. A real “company within the company” to better meet all the needs of aluminum customers.

The specificities of the sector and the generational change within the Vanin family have found a natural continuation in a spin-off: the birth of VaninAllumin srl.

The KanbanRocket team and the new VaninAlluminio team had the opportunity to work within the “Materials Management” project to:

- Redefine which codes to manage in kanban

- Correctly dimension the purchase kanban loops

- Redesign the physical supermarket

- Involve all major suppliers (definition of specifications, training and start-up)

- Implement our electronic kanban software: KanbanRocket

- Integrate KanbanRocket with the company ERP

We have thus obtained important results:

- The number of stock out has been reset

- Reduced average stocks and increased the inventory turnover index

- Automated entry of purchase orders from the warehouse

- Automated management of transport documents and warehouse loading / unloading

- Increased punctuality and completeness of delivery by suppliers

- Drastically decreased the time wasted on phone calls with the supplier to define dates, delivery methods and progress of procurement

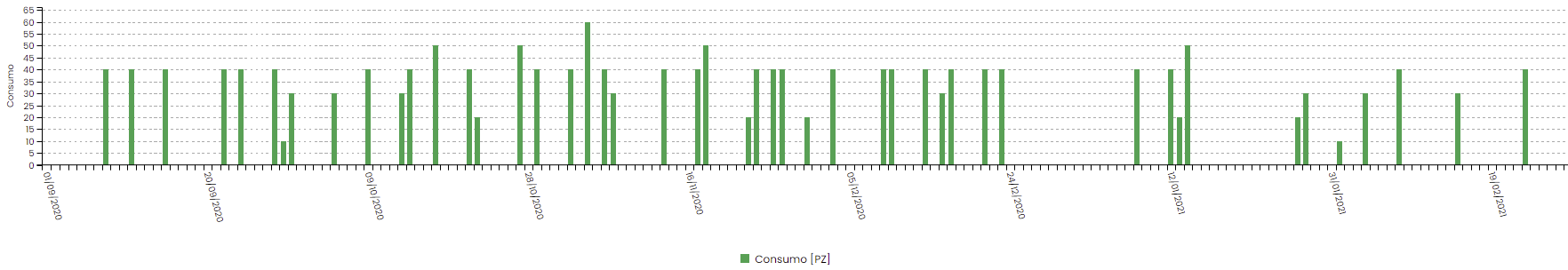

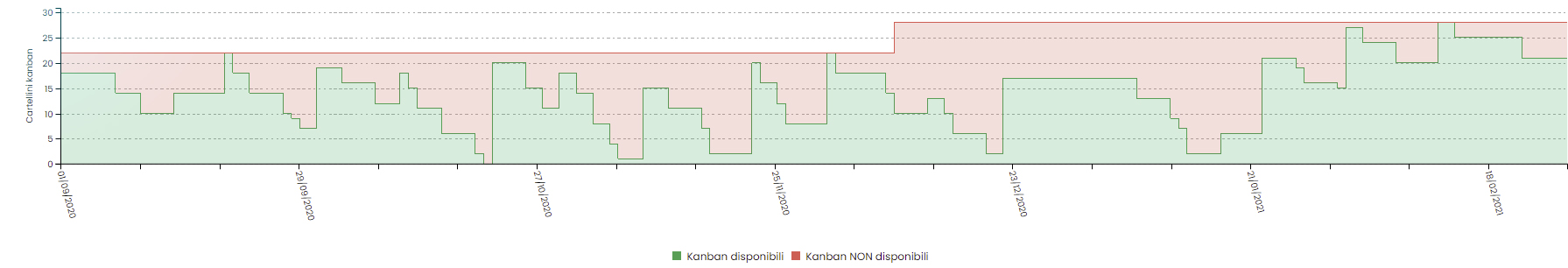

Example of regularization of daily consumption and average stocks for the SPASP2A-N code of VaninAlluminio managed within KanbanRocket

comments